Press Welding Flexible Copper Jumpers are developed from high conductivity based electrolytic grade copper sheets/foils. These are made using a press welding procedure where individual copper strips are fused through applying direct current as well as pressure without the need of foreign material. PVC Dipping covers are perfect insulation and flame retardancy UL94v-0 standard, the covers can hold 10KV and allows large current to pass.

Photo Shows:

Details of Flexible Laminated Copper Busbars

| Material | T2 99.95% copper foils/sheet |

Copper Foils Thickness

| 0.1mm, 0.2mm, 0.3mm, 0.5mm, 1.0mm |

Surface Finishes

| Black Paint

Electro brush Silver Plating

Tank Nickel or Tin Plating |

| Production Process | High Ampacity Flexible Connection

Molecularly Fused Laminates Ends

High DC Current Under Pressure Welding |

Current

| Typical: up to 2000 A

Possible: Up to 5,000 A |

| Flex parts of length | Up to 6.6 ft.(2meters long)

|

Width

| Up to 6.0 inch (152mm ) |

Max.Oeveall Thickness

| 1.25 inch (32mm)

|

| Testing | Resistance, Temperature Rise, Conductivity |

| Sample | Free |

Laminated Flexible Jumpers advantages:

1) Welding press many laminations improve electrical conductivity and add the transmission of current.

2) The feature of flexible enable us to be made busbars in various types.

3) Laminated copper shunts are flexible and easy to install.

4) Flexible laminate busbar is not easy to be broken after thousands times of bending.

All sizes can be customized. Just send us your drawings, such as PDF, JPEG, PNG,JPG etc.

We will quote for you in 1-2 working days !

Busbar Types :

| Nickel Plated busbar | Bare Copper Busbar | Tinned Copper Busbar |

|

|

|

| Insulated Busbar with Sleeving | Solid Busbar with Dipping | Insulated Busbar with Coating |

|

|

|

Technics Supports & Usage:

| Techinics Abilities | Cutting, Punching, Twisting, Bending, Plating, Riveting,Dipping, Coating, Welding, Stamping,Tapping, Brazing, Drilling, Milling, Sawing etc |

Plating Optional

| Nickel Plating

Silver Plating

Tin Plating |

| Insulation Type | Epoxy Coated

PVC Dipping Coated Heat Shrink Sleeves Adsorption |

| Hole Shape | Round Hole, Oval-shaped or Others |

| Edge Shape | Full Round Edge, Semicircle, Square Corner |

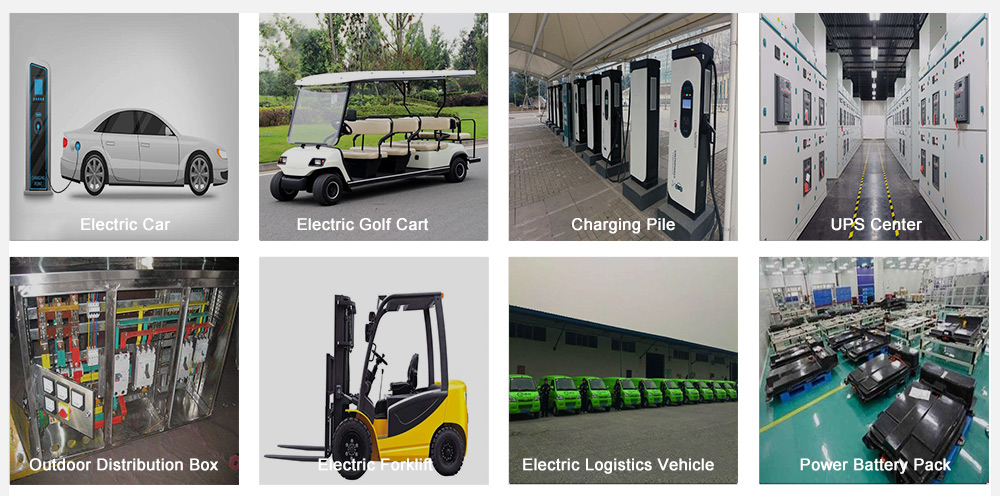

| Usage | 1)New Energy Vehicles 2)Battery Packs; 3)Power Supply Room; 4)Power Distribution Equipments; 5)Switchboards; 6)Panel Boards; 7)Low and Medium Voltage Switchgear; 8) Electric Bus, High Speed Train, 9)High Current & Control Equipment; 10)Busway Systems etc. |

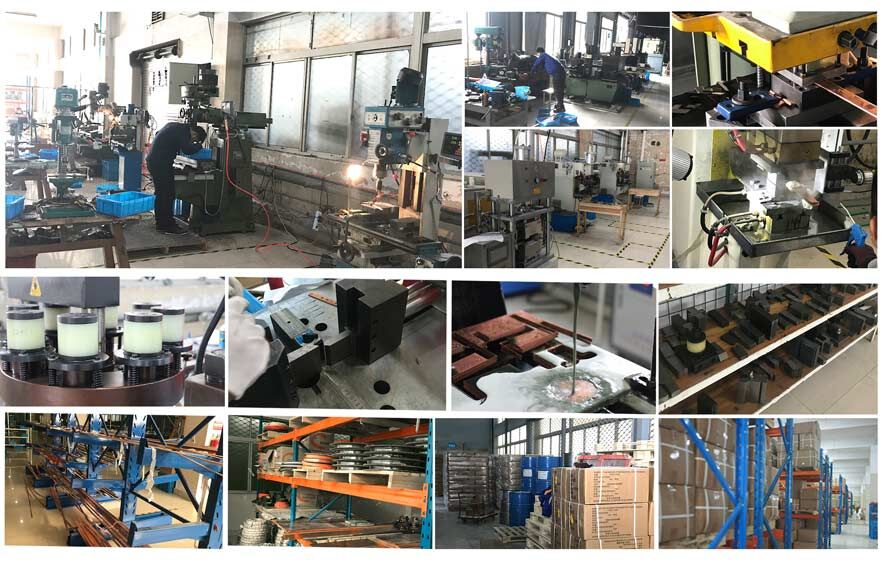

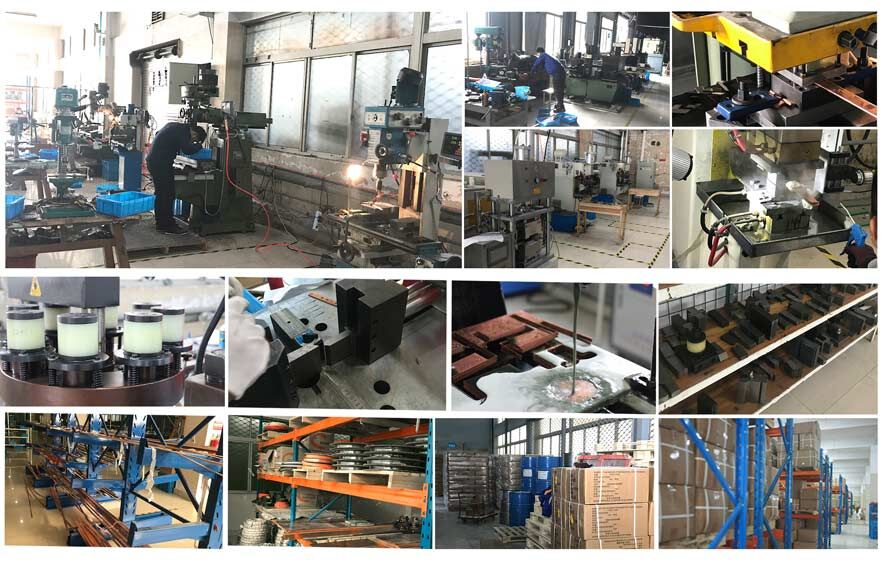

Busbar Technics Shows:

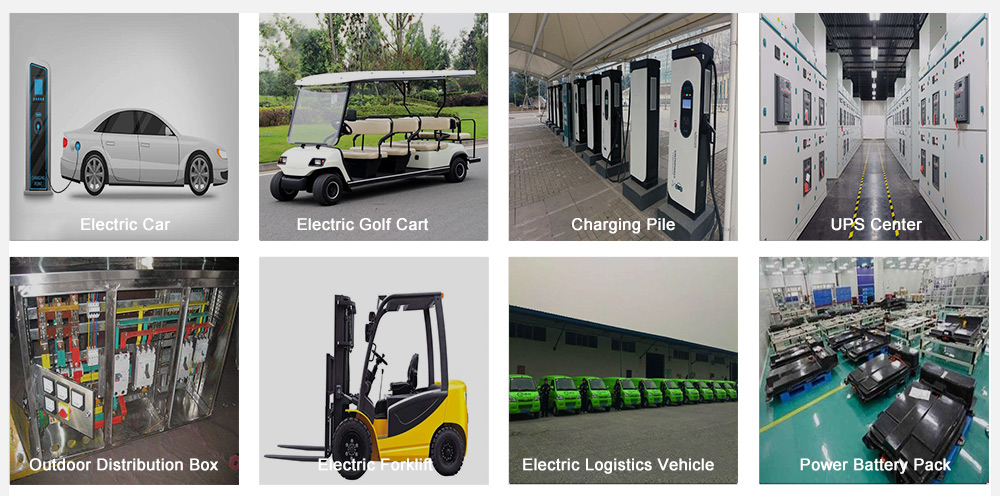

Usage Show:

Our Advantages:

Strong Manufacturer: We have 6000 m2 standard workshop to assure the stability of busbars

Strong After-sale Service: Our after-service team has 30 staffs. With professional busbar knowledge and more than 5 years' exporting experience, our team help to solve any problem during cooperation.

Timely Delivery: As to the standard copper busbar, we promise normal order will be delivered within 7 days. Non-standard copper bus bar delivery time, we can discuss.

Quality Guarantee: Material is tested before production to guarantee it is 100% new raw material. All busbars are inspected before delivery.

Competitive Price: We are professional factory to supply most competitive price with high quality. For long cooperation and large quantity, we can discuss discount price.

Company Show:

Inquiry Now !

Just call at 0086-577-61988720 or 86-15867770670, Mr Kevin Wu, Let's do long-term business.

Business mail is :s5@cnrhi.com

Wechat: kevin88hao

Skype: smilekevinh